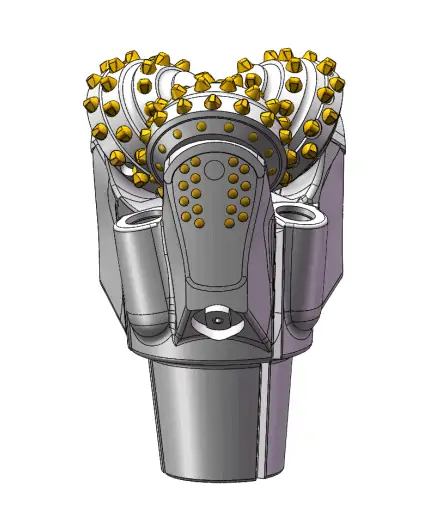

Tricone Bit

Many experiences inmanulacturing tricone bit for years, the roller cone bits designed and manufactured by HAOQI DRILLING show high perfomance and high reliabiity proved by the on-site testing and operation for thousands of hours. Each part of the design and processing technology of HAOQI DRILLING roller cone bit is able to meet he needs of the customers

Production Process of Tricone Bits

5 Steps and Requires a high degree of precision and technical understanding for Tricone Bits. Here is a simplified sequence of the production process:

Design: Engineers use CAD software to design the bit based on specific drilling requirements.

Material Selection: High-quality, durable materials like tungsten carbide and Hard-metal alloy are selected.

Manufacturing: The steel body is shaped, and teeth or inserts are added into the cones.

Heat Treatment: The bit is heat-treated to enhance hardness and durability.

Quality Control: Each bit is inspected to ensure it meets specifications and standards.

Tri-cone bits are designed for different equipment applications including mining, HDD, water wells and more. It mainly occurs at the bottom of hole components. The teeth of the drill bit use mechanical friction and rotation to reach the rock surface. It consists of three tips that move in a rotating manner. Each tricone bit has a bearing for smooth rotation.

HAOQI is a professional manufacturer of tricone bits using different grades of materials such as alloy teeth, metal or rubber seals, etc. We offer custom tricone bits designed to increase the efficiency of a project while increasing cost. Our team also offers fast delivery, large stocks and different sizes of tricone bits .

TCI Tricone Bit

Steel Teeth Bit

Mining Rock Bit

HK Series Tricone Bit

Metal-face seal, where all relative rotary motion occurs between two lubricated metal surfaces.

New processes of hard bearing, hardfacing and cone bearing silver plating are used to improve the load capacity anti-galing ability and stabiily of the bearing.

A Better choice when operating in high-speed, high temperature and abrasive conditions.

HL Series Tricone Bit

HL series bit is a kind of rock breaking tool indispensable for geological exploration,oil drilling and various drilling industries.Its strong stability, high reliability, good hydraulic effects, high rock breaking effciency and long service life.

Single metal seal, where An integrated wear-resistant ring has been added inside the rubber sealing ring. This integrated wear-resistant ring is typically made of metal and serves the purpose of providing a wear-resistant surface during frictional motion to reduce friction and heat generation.

Reducing Frictional Area: The presence of the integrated wear-resistant ring significantly reduces the area of friction between the rubber sealing ring and the sliding friction surface. This can reduce the heat generated by friction, thereby slowing down the aging and failure of the rubber sealing ring.

A More economic choice when operating in high-speed, high temperature and long-lifetime.

HLW Series Tricone Bit

composited seal, where Polytetrafluoroethylene (PTFE) ring has been added inside the rubber sealing ring.

New processes of hard bearing, hardfacing and cone bearing silver plating are used to improve the load capacity anti-galing ability and stabiily of the bearing.

A cost-effective choice in HDD,Deep Water well.

Bearing stucture

journal bearing

The solid lubricating layer on the surface of the roller cone bit’s bearing can transfer the heat of the bearing surface.

The wearing-resistant alloy bead welkded on the bearing surface of the leg can mitigate the friction between the leg and the cone to reduce the wearing and improve the bearing capacity anti-snapping ablity and stability of the bearing

Silver plated cone bearing—solid lubricant coating transfers heat away from load surfaces.

Float bearing

Plating a floating ring between the inner hole of he cone and the neck journal of the leg makesa adial floating bearing: placing a ring-shaped float gasket onto the thrust surface between the cone and the leg makes an axial floating bearing this way,

the rotary speed acceptable for the cone can be increased by 1 time if under the same working conditions of the driling well, and the heat generated by the friction of sliding can be significantly reduced, extending the service life of the bit

Rolling bearing

Putting a cylindrkal rolling element into the groove of the shell of the cone increases the slze of the neck joumal and the rolling element.

Making the cylindrkal rolling element hallow can enhance the smoothness and impact esistance of rolling and increase the storage pace of grease lubricant, so as to improve the ubrication conditions

The outer surface of the cylindrical ralling element is a surface with a certain corwedty, which mitigates the edge offact on both ends of rolling and extends the service le of the rollen

Tricone Bits with Optimal Features

The circular/non-circular lock ring in the roller cone bit uses the synthetic material, which shows greater wearing resistance and sealing rellabaty than traditional sealing materials.

After adding special materials to the rotating-shaft composite lock ring in the roller cone bit, the coeffcient of friction can be lowered by over 40% if under the bench test conditions thus improving the wearing resistance by 2-3 times.

If using new high-viscosity lubricant grease with good thermal stability, the double-cil storage lubricatian compensation system made through precise design and processing can significantly improve the speed of balancing the pressure inside and outside the besring, enhance the bearing capacity of the bearing and extend the servie life of the sealing and of the entire bearing system.

Special hydraulic structure with double extended nazzles can remove large amount of drilling cuttings developed from drilling operations,and eliminate driing cutting dead area at the bottom hole,so speed up remaval of the drilling cuttings from the hale.

Three side nozzles and one center nozzles of the tricone bit can increase capacity of deaning hole,expedite upward flow of drilling cuttings.

Tricone Bits with Optimal Features

Center nozzle

Center jet can avoid bit balling,eliminate resoting area of fluid at bottom hole, expedite upward flow of cuttings and improve ROP. it is suitable for driling in soft to medium soft formatons with low compressive strength and high drilability.

Diamond enhanced inserts

Better drilling performance can be achieved when drlling in more abrasive,hard and extreme hard formations by arranging diamond enhanced inserts in heel gage rows and head OD.

Convex crested wedge compact

Convex crested wedge compact is with the features of high effectively cuttng abilty and strong anti-breaking ability, which can increase ROP and improve service ife of bit effectively. It's suitable for formations from medium soft to medium hard.

Directionaljet

Directionaljet feature (J) enlarges ateral flow area on botiom hoe and is helpful to bottomhole cleaning and increase of ROP.Suitable for soft to medium soft formatons of low compressive strength and high drilabilty.

Bit head OD stabilization

The function of bit head OD stabilization s good for improving working situation of bit,which can effectively protect head and compensator recess in directonal well and horizontal well.

Conicalspherical compact

Main cutters of bit are conica spherica compacts, which are suitable for drllng in hard brittle formations.

Head OD protection

Special inserts are strategically arranged on head OD to efectively reduce head wear in abrasive formation and directional and horzonta wells and extend bit life.

Diamond inserts on gage protection area

Beter drillng perormance can be achieved when drlling in the more abrasive directional well and horizonal well by arranging diamond enhanced nserts in head OD.

Hard plasticformation cutting structure

Unique designing parameters and wider insert crest enlarge rock-breaking volume on bottom hole and increase bottom hole coverage.At the same time,shear sliding distance of inserts at bottom hole is made arger and ROP of the bit in hard plastic formation is increased.

The Basic Knowledge About Tricone Bit

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

The FAQ About Tricone Bit

We offers professional custom designs that save you both production costs as well as installation time while maintaining a certain level of quality throughout every step in the process so we can guarantee customer satisfaction under any circumstance — no matter what challenges they face or where around world their business may operate

12 1/4″ IADC537, 8 1/2″ IADC537, 15 1/2 ” IADC537, 17 1/2″ IADC537, 9 7/8″ IADC637 are the most hot size we export.

Depending on the shipping method you choose, if it is air freight, the receiving time is generally within 7 days, if you choose sea freight, the receiving time is about 30-45 days.